Study of the Impact of Biofouling on Ship Resistance Using Autodesk CFD

Keywords:

Biofouling, Ship Resistance, Fluid Flow, Maritime Industry, PreventionAbstract

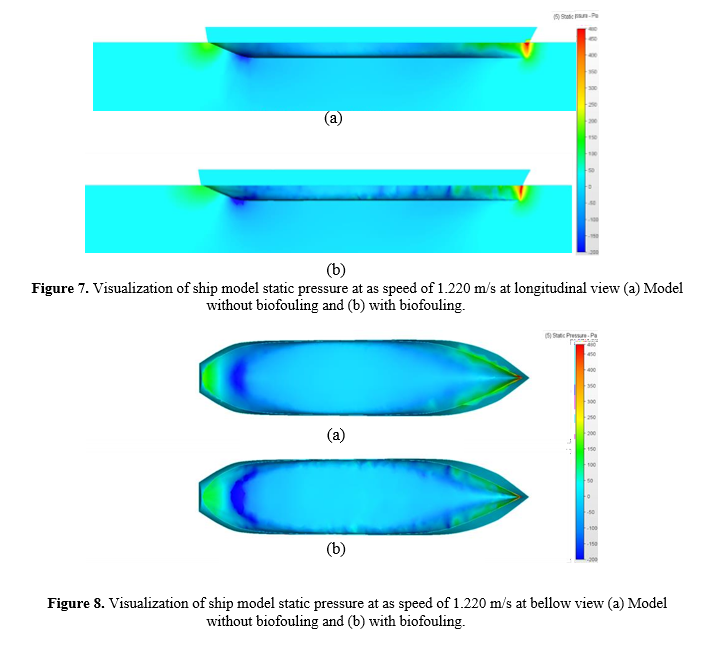

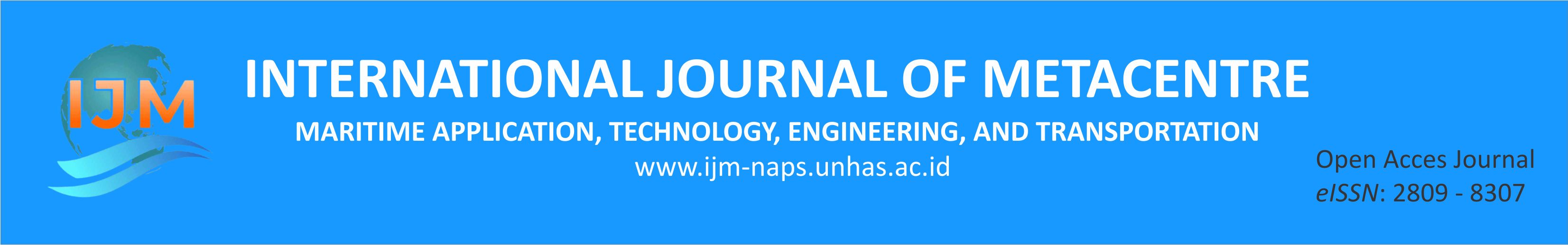

Biofouling, the accumulation of marine organisms on ship hulls, poses a substantial challenge in the maritime industry. Over time, organisms like algae and molluscs adhere to hull surfaces, creating a biofouling layer that disrupts water flow and increases ship resistance. This study investigates the effects of biofouling on ship resistance and fluid flow patterns along the hull. Data collection involved measuring key ship dimensions, analyzing ship lines plan drawings, and measuring biofouling thickness. Autodesk Computational Fluid Dynamics (CFD) software was used to calculate ship resistance and analyze fluid flow along the hull. Two conditions were compared: a hull without biofouling and a biofouled hull. At a speed of 1.220 m/s, the biofouled ship model exhibited a resistance of 3,739 N, while the clean hull had a resistance of 3,280 N, indicating a 13.642% resistance increase due to biofouling. Fluid flow analysis revealed complex flow patterns along the biofouled hull, potentially reducing operational efficiency. These findings underscore the importance of biofouling prevention and control measures in minimizing resistance and maintaining operational efficiency. A deeper understanding of fluid flow characteristics related to biofouling allows ship operators and companies to make informed decisions about vessel maintenance, reducing environmental impacts and operational costs. This research contributes to addressing biofouling challenges in the maritime industry.

Downloads