Experimental Test of Tensile Strength of Barge Deck Plate Welded Joints

Keywords:

Joint strength, Electrodes, Welding, Tensile strength, ExperimentAbstract

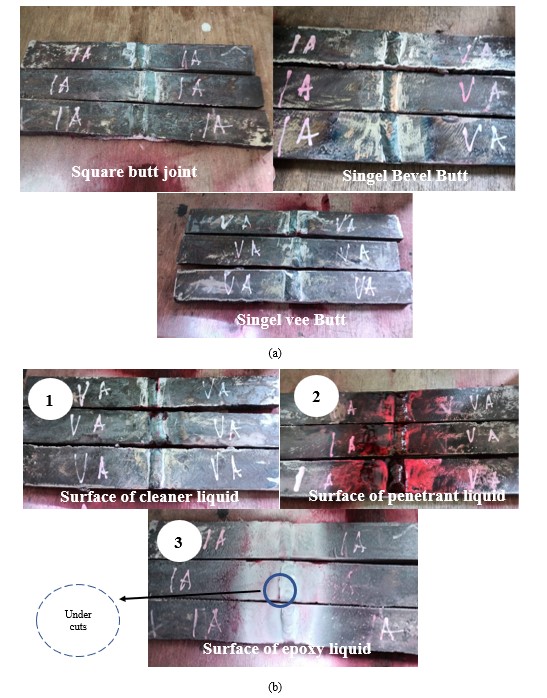

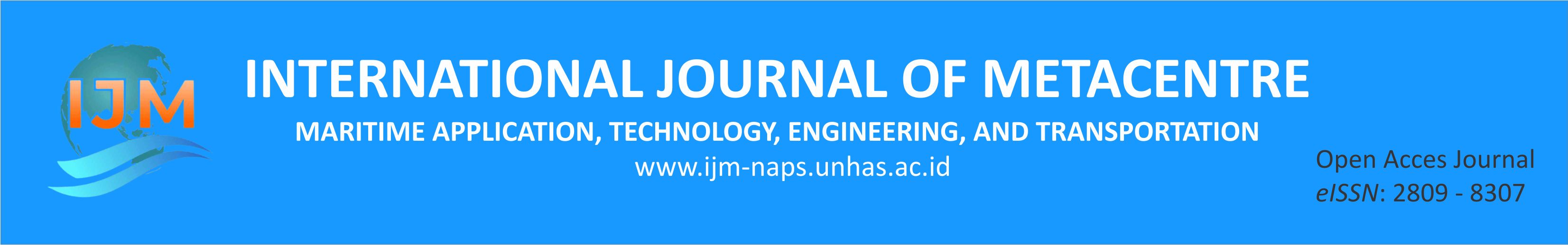

American Standard Testing and Material (ASTM) A36 is a low carbon steel, and commonly used as material of shipbuilding. Joining of steel can cause decreasing of its strength. The purpose of this study was to determine the tensile strength of joints of ASTM A36, consisting of square butt, single bevel butt, and single vee butt joints. The research methode is experimental. The specimens are made of steel for the ship's decks, which are connected using three types of joints. Each type of connection involves as many as three specimens, so there are a total of nine specimens. Before the tensile test is carried out, the specimen is subjected to a penetrant test to detect weld defects. It was detected that the specimen had broken off at the weld joint. The experiment result shows that the strongest joint from tensile strength point of view is single vee butt joint (198.80 MPa), followed by single bevel butt joint (182.19 MPa) and, square butt joint (168.51 MPa).

Downloads